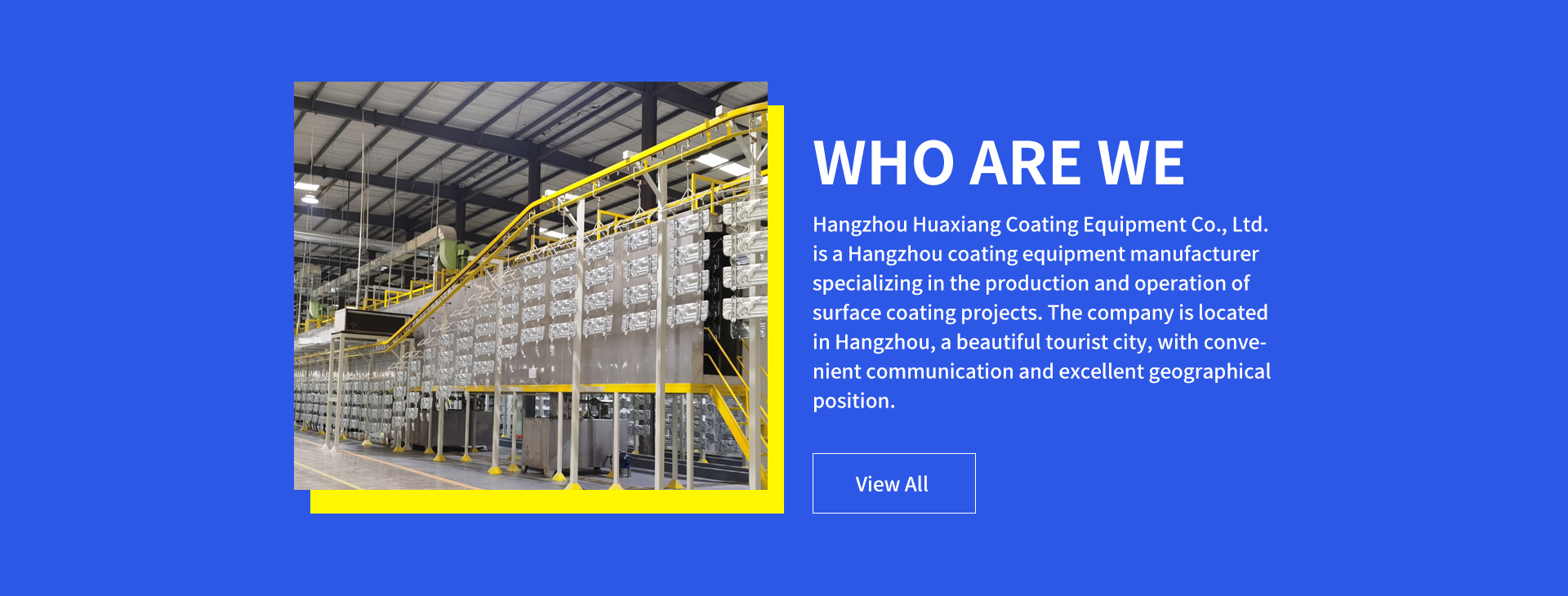

1. Electrostatic Powder Coating Machine Overview and Components

An Electrostatic Powder Coating Machine is a system that uses electrostatic charging to apply dry powder to surfaces. Key components include an electrostatic spray gun, powder hopper, high-voltage generator, grounding system, recovery unit, and curing oven. Advanced models integrate IoT sensors for real-time monitoring of powder flow and voltage adjustments.

2. Applications of Electrostatic Powder Coating Machines

Widely used in automotive (wheels, engine parts), aerospace (aircraft components), appliance manufacturing, and furniture production. These machines deliver uniform, durable coatings on metals, plastics (with primers), and composites, ensuring corrosion resistance and aesthetic appeal.

3. Pricing of Electrostatic Powder Coating Machines

Prices range from 5,000formanualsystemsto200,000+ for fully automated lines. Entry-level electrostatic powder coating machines cost 5,000–20,000, while industrial-grade systems with robotic arms and high-efficiency recovery units range from 50,000–200,000.

4. Proper Operation of Electrostatic Powder Coating Machines

Ground workpieces to ensure electrostatic adhesion. Adjust voltage (40–100 kV) and airflow (10–30 psi) based on material and powder type. Maintain a 6–12-inch spray distance. Cure coated parts at 300–450°F for 10–30 minutes. Clean nozzles and filters after each use.

5. How to Choose an Electrostatic Powder Coating Machine

Evaluate production volume: Manual systems suit small workshops; automated lines handle 500+ parts/hour. Prioritize stainless steel construction for durability. Verify compliance with OSHA and EPA standards. Ensure compatibility with epoxy, polyester, or hybrid powders.

6. Safety Precautions for Electrostatic Powder Coating Machines

Use explosion-proof ventilation to manage combustible dust. Wear NIOSH-approved respirators (N95+) and anti-static gloves. Regularly inspect grounding systems and electrical components. Store powders in dry, cool environments.

7. Cost-Efficiency of Electrostatic Powder Coating Machines

Electrostatic systems reduce material waste by 90% through high recovery rates (95%+). Energy-efficient ovens with heat recycling cut power consumption by 30%. Automation lowers labor costs by 50%, achieving ROI within 2–3 years for high-volume users.

8. FAQs About Electrostatic Powder Coating Machines

Q: What is the powder recovery rate of an electrostatic powder coating machine?

A: Advanced systems achieve 95–99% recovery using cyclone separators and HEPA filters.

Q: Can electrostatic machines coat heat-sensitive materials?

A: Yes—UV-curable powders and low-temperature ovens protect plastics and wood.

Q: How often should spray guns be cleaned?

A: Clean nozzles daily and perform deep maintenance weekly for optimal performance.

Q: Are electrostatic powder coating machines eco-friendly?

A: Yes—zero VOC emissions and high powder reuse align with sustainability goals.

Q: What certifications ensure machine safety?

A: Look for CE, UL, or ATEX certifications for compliance with industrial safety standards.

This guide provides critical insights into electrostatic powder coating machines, enabling businesses to select, operate, and maintain systems for superior finishes and operational efficiency.

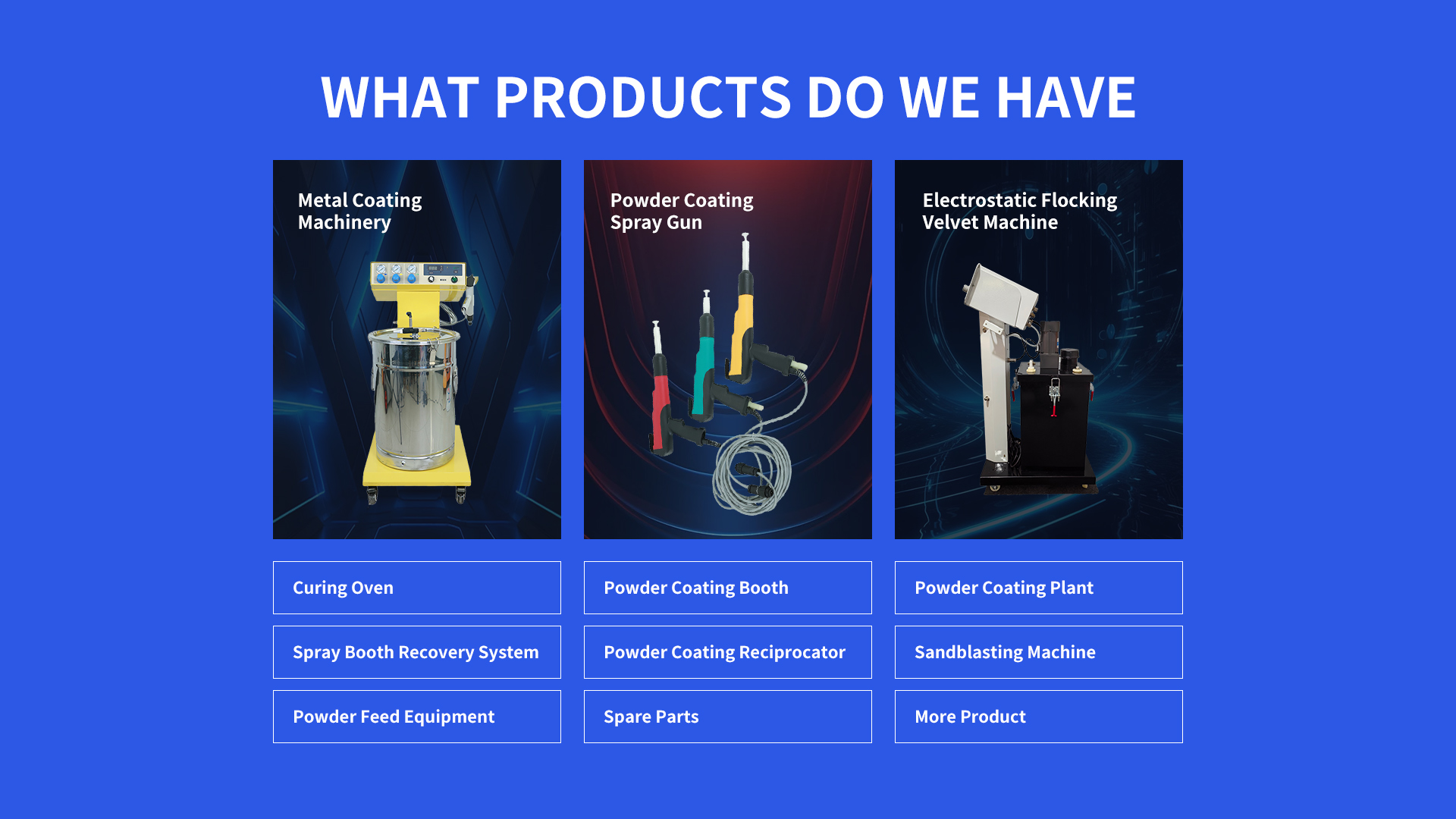

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com